Stamped Asphalt

Stamped Asphalt is a high tecnology solution, developed thanks to great passion and know-how, built through the years. Experience and dedication are the meaning of a product with specific phisical and mechanics features, as:

Long Life

Flexibility

Adherence

Color Stability

Skid

Safety

This set of features, contributes to define our concept of “Safety-StreetCoat”, a binomial of safety and fineness.

Stamped Asphalt guarantees road safety in every weather condition and different urban contexts, thanks to accurate labor tests and installation tries.

Advantages of Stamped Asphalt

Short time application

Reduced maintenance costs

Possibility of localized restoration

Usage of already existing paved surfaces

Low environmental impact of materials

Design and nice color effects

When there’s an asphalt surface in good conditions, with at least 3 cm thickness, it’s possibile to work on it, without making a new asphalt paving. Otherwise, work starts with a new bituminous surface, to cover all the interested area.

Working Process

Working process is composed of 5 steps:

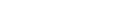

1) We place the asphalt (if not already made), or we heat it using a UV-technology heating machine;

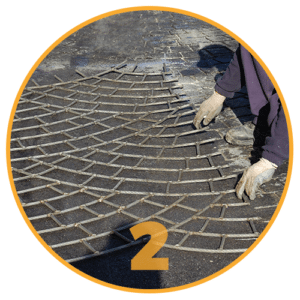

2) We place the iron template/shape on the asphalt surface;

3) We print the template, previously placed, whit the help of a vibrating plate;

4) We remove the template and we repeat the same work, until the entire area has been covered;

5) We coat the asphalt with multiple hands of painting;